Non-Intrusive Railway Track and Train Monitoring

MoniRail is a leading provider of railway solutions formed through the ICURe programme at the University of Birmingham and supported by Innovate UK.

It provides a non-intrusive measurement system that combines sensor units with a data analytics platform for railway condition monitoring and track deterioration. Used on-board ordinary railway vehicles whilst operating in-service, it allows engineers to continuously monitor the state of railway infrastructure, without interrupting rail services.

A compact measurement system for in-service passenger trains

The MoniRail measurement solution, developed from over 20 years of research at the University of Birmingham, provides track and ride quality data comparable to dedicated measurement trains. It uses lightweight, vehicle-mounted sensors to continuously monitor track geometry, ride comfort and vehicle dynamics.

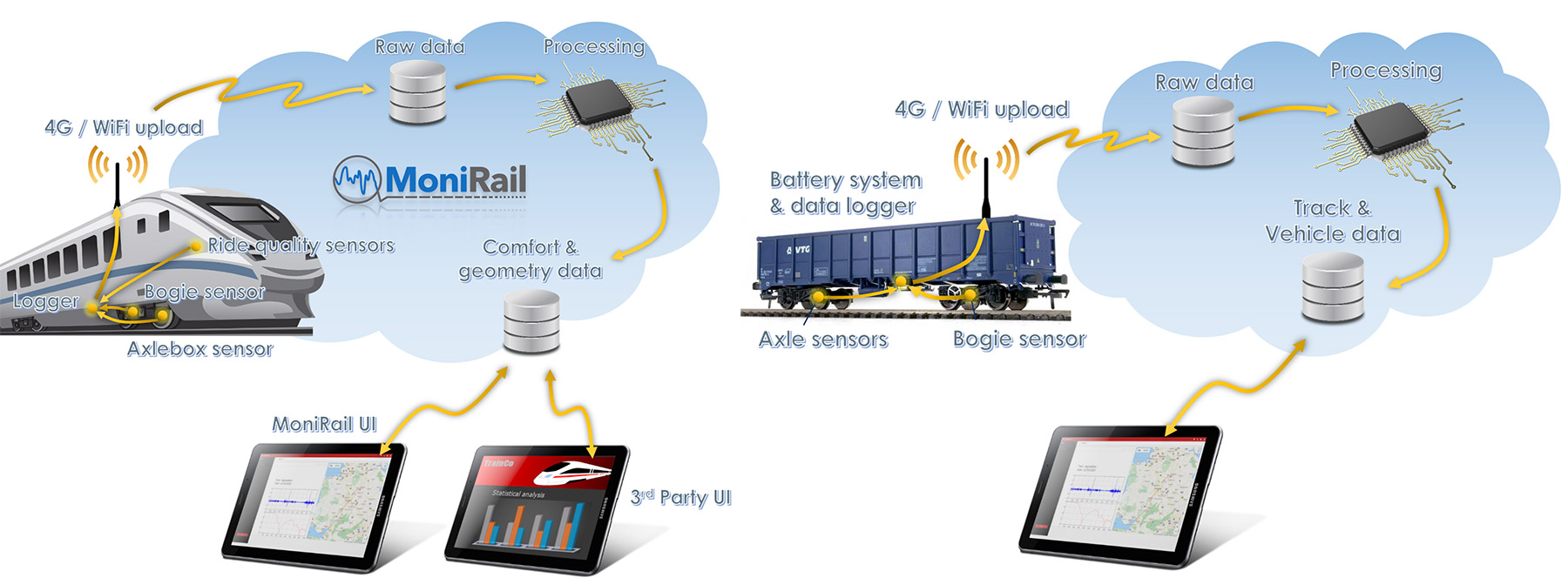

The system is equipped with Inertial Measurement Units (IMUs) on the vehicle body and optionally on the bogie and axlebox. These sensors capture detailed motion data, which is processed through our cloud-based analytics platform. The platform converts raw sensor data into actionable insights, offering a clear picture of track and vehicle conditions over time.

Monitoring the quality of the track from in-service trains in this way gives you a better understanding of the evolving condition of the assets, helping you to build up a clearer picture of the train and track conditions over time. This enables accurate prediction of potential problems and allows for early detection of railway track degradation. Preventative maintenance can therefore be implemented accordingly, and problems can be tackled promptly, before they escalate into causing a major fault or delay.

Improves Efficiency

The integrated hardware and software solution supports continual data analysis, helping to improve performance and reduce maintenance costs.

Fit and forget

Designed for easy installation and low-maintenance, the solution monitors track conditions in real timewithout disrupting daily operations.

Real-Time Data

Processed sensor data delivers accurate track condition and vehicle performance data combined with accurate position information.

Predictive Maintenance

MoniRail empowers railway operators to undertake predictive maintenance, by providing early detection of potential issues. Ensuring the longevity of rail assets and enhancing ride quality.

How does it work?

The on vehicle monitoring hardware collects data from the onboard IMU unit sensors. From there, the data is automatically processed using a mathematical-based model, providing accurate identification of track conditions and geo-spatial positioning.

This recorded data is transmitted to the cloud for analysis in near-real-time, providing live, up-to-date information that can be easily viewed on the online portal. MoniRail’s intelligent software algorithm interprets data from multiple sources, supplying reproduceable information to those who need it.

As an integrable system, the sensors are non-intrusive and can be fitted during routine maintenance, whilst the accompanying software is cloud-based, easily scalable, and delivers automated information.

MoniRail’s bespoke in-service monitoring solution is continually evolving, driven by the organisation’s academic partnership and feedback loop from the BCRRE (Birmingham Centre for Rail Research and Education).

Why use MoniRail?

- Save money, time, and unnecessary maintenance by identifying and tending to problems sooner

- Optimise maintenance and improve network reliability

- Optimise track speeds and decrease wear through rough ride monitoring and increased capacity options

- Benefit from MoniRail’s 50 years of combined experience within the rail industry, centred around sound, 20+ years of world class research and analysis

- Enjoy better work planning by detecting problems early and implementing interventions ahead of time

- Deliver engineer appropriate data outputs which help prioritise maintenance

- Decrease boots on ballast and improve customer experience through automated data collection, processing and analysis